Black Powder™ (Black Powder) is an oil and gas industry term for the abrasive, reactive contamination present in all hydrocarbons and hydrocarbon derivatives. It is a mix of various forms of iron sulfide and iron oxide, along with other compounds and substances including chlorides, sodium, calcium, mill scale, sand, glycol and varying types of ‘dirt’, such as silica and other particulate. It is also known as rouge, black dirt, brown dirt, red dirt and various other names.

- Black Powder initially forms as a sulfur-based corrosion product from microbial and chemical interactions.

- The accumulation of the abrasive Black Powder promotes corrosion and erosion and further breakdown of the pipeline and equipment throughout hydrocarbon pipelines and facilities.

Black Powder originates in producing formations and precipitates out throughout the hydrocarbon value chain: during transportation, processing, storage, fractionation, refining, petrochemical production and loading and offloading.

Sources of Black Powder

Corrosion

- Bacteria formation: Sulfur and acid producing bacteria are dependent on water and iron reactions to initiate the formation of Black Powder contamination.

- Chemical formation: Moisture, hydrogen sulfide, temperature and/or pressure variance are further catalysts for the development of Black Powder.

Erosion

- Once formed, Black Powder continues to build due to both corrosion and erosion as hydrocarbons progress downstream – all piping and equipment is vulnerable to its erosional impacts.

- If not removed at various spots in the hydrocarbon value chain, it will continue to build due to erosional forces and eventually plug off pipelines, meters, valves, heat exchanges, reboilers and other equipment, including conventional depth media filters.

Capturing Non-Ferrous Contamination

BPS’ Magnetic Separator systems capture Black Powder particulate contamination, which includes both ferrous and non-ferrous particles. It is well known that ferrous materials are attracted by magnetic forces; however, the capture of non-ferrous particles by magnetic forces is less understood.

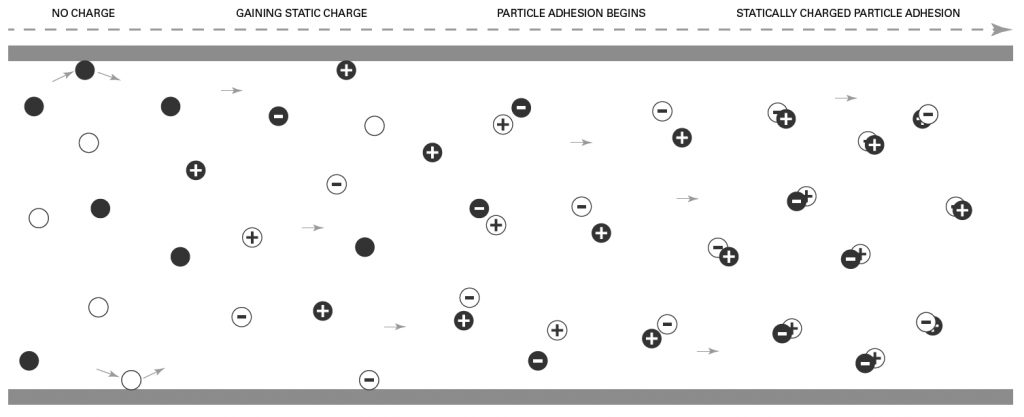

Non-ferrous particles are magnetically captured due to cross-contamination with ferrous particles. All particulate contamination becomes electrostatically charged due to physical interactions with other particles and surfaces, such as in pipelines or in hydrocarbon processing applications. This electrostatic charge causes negatively and positively charged ferrous particles to adhere to positively and negatively charged non-ferrous particles. The ferrous particle in this particle pair is then drawn to the magnetic element within the Magnetic Separator System.

There are other forms of adhesion that also cause the pairing of ferrous and non-ferrous particles, including embedding and capillary forces, although static pairing is the largest contributor to this process.

How electrostatic charge is induced

Electrostatic charge is generated whenever there is friction between two bodies moving relative to one another. Charge generation occurs on the molecular level at the interface of any two unlike materials, so a static charge will be generated in any moving fluid, with positive or negative charges moving from the fluid onto the bounding surface.

The causes of electrostatic charging include the following examples:

- Friction between the pipe walls and the moving fluids.

- High fluid velocities.

- Passage of fluids or gasses through separator elements or other microporous structures.

- Turbulence created by pumping or compression, particularly centrifugal units.

- Fluid discharging on to the free surface of a storage tank.

Contaminants gaining charge

The amount of charge generated by the flow of a hydrocarbon liquid and filtration is related to several fluid and separator properties. Charge generation typically strengthens with increasing flow, reducing fluid conductivity, with certain additive packages and with increasing viscosity. Charge accumulation increases with lower fluid conductivity, lower temperatures, and higher viscosities.

Introduction to Black Powder Contamination

Black Powder contamination is a widely used term for a highly pervasive particulate contamination found in all hydrocarbon facilities and pipelines, water systems, petrochemical powders, and other fluid and gas systems…

Black Powder Composition & Formation

Black Powder’s composition is variable; it depends on geographical location, subsurface formation elements and compounds, types of hydrocarbon, facility/process type, introduced compounds/chemicals…

Managing Black Powder

Industry Standard vS Black Powder Solutions’ technology

Cyclones, separators, cone and basket strainers with fine mesh are used to reduce Black Powder contamination levels, but are not efficient to sub-micron levels and are subject to plugging and loss of structural integrity.

For hydrocarbon condensates, light crude, heavy crude and refined products, very little filtration is utilized. Damage to flow meters, valves and pumps is very costly. Traditional filtration used in these applications is mesh screens in cone strainer and basket strainer formats that are designed to stop contamination in excess of 100 microns.

Industry Standard

Presently, the majority of measures employed to deal with Black Powder are reactive not proactive such as pigging and chemical cleaners resulting in significant down time and costs.

Present proactive measures are to treat sour gas pipelines with corrosion inhibitors, employ lined pipe and, when possible, replacing the steel pipe with plastic pipe.

For gas pipelines, traditional filtration consisting of cartridge filter elements manufactured from paper, fiberglass or polymer media with various rated filtration capabilities are employed to reduce Black Powder levels. These technologies are inefficient because they plug off quickly and require costly change outs resulting in reduced production. These technologies present flow restriction that cause stress on the pumping or compressor systems requiring increased horse power to maintain flow.

Black Powder Solutions’ Technology

Black Powder Solutions (BPS) provides proactive management practices to reduce the contamination levels, mitigating the overall negative impact Black Powder has on pipeline operational integrity. The solution to this problem is to employ Magnetic Separation Technology in strategic locations throughout the pipeline system, refineries, chemical plants, city gates and loading facilities.

Over the past 15 years, significant improvements in rare earth magnetic technology have created the ability to use magnetic fields as a filter or separator medium which is environmentally and user friendly, highly efficient and cost effective.

BPS designs and manufactures Black Powder Separators in a modular format for full flow gas and hydrocarbon fluid pipelines that remove ferrous and non-ferrous black powder contamination. This is accomplished by three methods:

(1) Entrapment of the iron particles mixing with the non-ferrous during flow.

(2) Naturally occurring static charge created by the flow of gas or fluids through pipes, referred to as static adhesion. The ferrous and non-ferrous particles are charged and marry up when they contact in flow. When exposed to BPS Radial Magnetic Fields, they attract and trap to the Magnetic Separator rod surface.

(3) Capillary forces can also bind non-ferrous particles to ferrous particles, although it is not as common.

In natural gas and oil pipelines, binder materials such as paraffins, glycols, and asphaltenes marry up with fine ferrous and sand particles trapping to the magnetic fields when passing through the Black Powder Separators.

The Black Powder contamination trapped on the Magnetic Separators is easily removed and stored in mineral bags. When the composition is primarily iron sulphides, there is opportunity for auto-ignition (smolders and flames), precautions must be taken to saturate the Black Powder with a chemical to neutralize it.

Removing and monitoring the quantities of the Black Powder in strategic locations along the transmission lines will lessen the erosion factor and may act as a monitoring tool for pipe wall life cycle.

Prime locations for the employment of BPS Separators to reduce contamination levels is loading and offloading of product at port facilities, prior to LNG plants, refineries, gas chemical plants, metering stations and power plants. Cleaner product entering these facilities will improve production and lower operational costs by reducing premature process equipment component wear.